044-722-4262

3-600 Kosugi-cho, Nakahara-ku, Kawasaki-shi, Kanagawa

Kosugi 3rd Avenue 1F

Business hours: 10:00-19:00

New & Restocked Frames

2019.08.05

Sabae Factory Tour Vol. 3

The other day, one of our guests asked me, "Have you written more about Sabae yet?" I will do my best to write about Sabae again today.

In the previous issue, we introduced the printing of eyeglass frames, and this time we would like to introduce the manufacturing site of metal frames.

In discussing metal frames, we must first talk about the material.

NT alloy (alloy of nickel and titanium)

pure titanium

beta titanium

German silver

Gum Metal

stainless steel

………..

In fact, there are many types of metals that can be used for eyeglasses.

Among these, the metal that is most compatible with glasses is generally said to be titanium material.

And Sabae's titanium eyeglass processing technology isbest in the worldIt is said that

Even Western designers outsource eyeglass production to Sabae, rather than to France, Italy, or China, because of the complex designs that are difficult to manufacture.

Let me preface this by saying that I am sorry for the length of time it has taken me.

We visited two of Sabae's metal factories, Fuji Optical and Sanko Kogaku, both of which have such technological prowess.

Fuji Optical specializes in the production of beta-titanium frames, and Sanko Optical specializes in the processing of rubber metal, a metal developed by a Toyota research institute. Both companies' frames can be found at Glasses of Osaka.

Now, it is said that metal frames are generally completed in 250 to 300 processes.

In very simple terms.

The process is as follows: make the part - weld it - polish and plating it.

Each part is placed on this press machine and pressed into a mold to create its shape.

The before and after images are easy to understand, but the shape will never be as beautiful as the one you see in your hand in a single press.

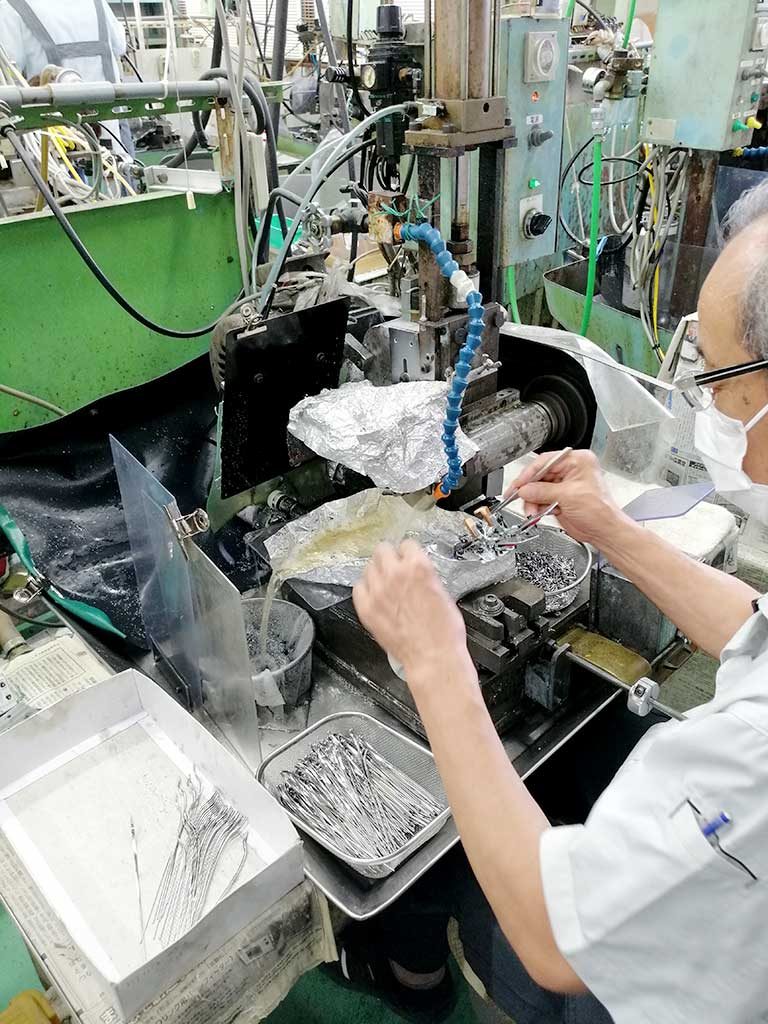

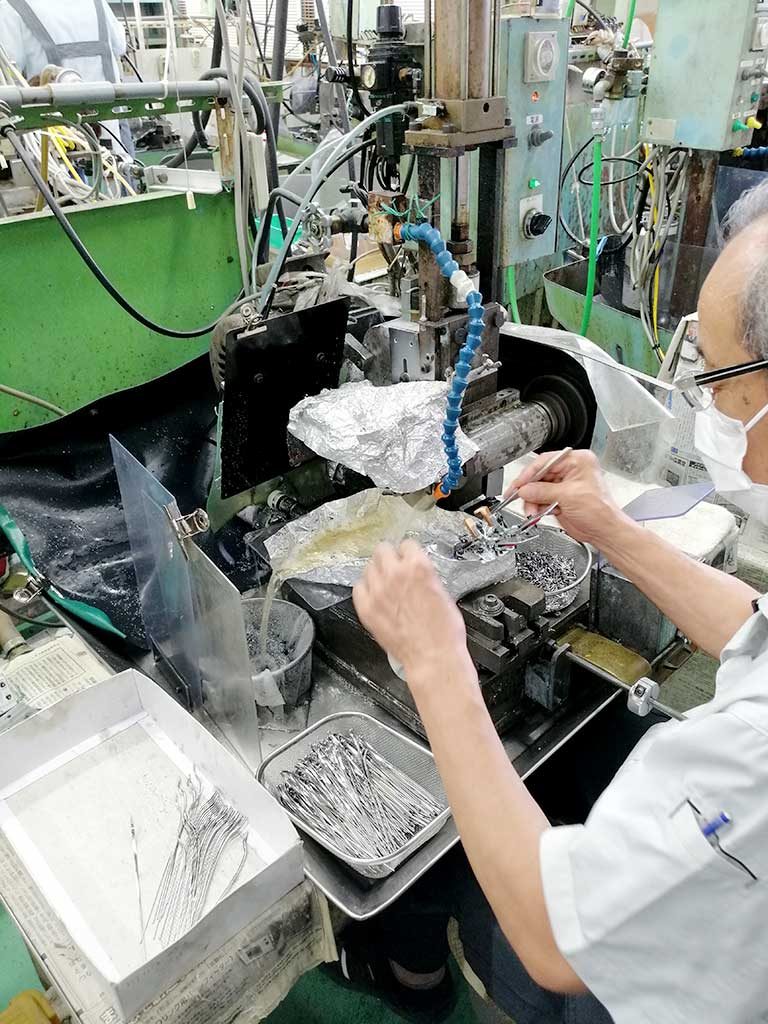

It is a little hard to see, but this is a picture of the cutting process for each part. All the work is done by human intervention.

For more information on brazing, please click here.

Argon gas is injected into the welding chamber to prevent air from entering and to heat the welding process all at once. This jig was also developed by the company.

This is a machine that winds the rim wire of the front part of the frame.

Please see the video here as well.

The shape of the glasses is created by winding the beta-titanium rim wire tightly. Moreover, it is not just rolled up, but it is rolled up three-dimensionally in a curve that fits the lens nicely.

After the parts thus made are welded and attached, they are polished to make them shiny, depending on the design. A frame set up like this is rotated in a circular motion for hours, and the polishing agent seen below hits the frame to clean it.

It is turned around and around in a machine like this.

We will polish not only plastic frames but also metal frames that need polishing.

We also met a craftsman who has been working in this field for 50 years, and were able to witness his skillful techniques.

Finally, they are assembled according to the blueprints, fine-tuned, and shipped.

We were given a good look at the manufacturing process in Sabae, and I thought it was unique in that human hands are involved in almost every single process.

Sabae's eyeglass industry is basically based on the division of labor, and many companies have outstanding technology in a single field, but these two companies also impressed us with their creative manufacturing techniques, combining general-purpose machines with their own originally developed machines.