044-722-4262

3-600 Kosugi-cho, Nakahara-ku, Kawasaki-shi, Kanagawa

Kosugi 3rd Avenue 1F

Business hours: 10:00-19:00

New & Restocked Frames

2019.08.05

Sabae Factory Tour Vol. 2

In this issue, we would like to introduce you to a factory tour in Sabae, the birthplace of eyeglasses. We hope to make it as easy to understand as possible.

Our first stop was Fine Ltd.

https://www.fineltd.jp/

This company does special printing on metal and resin.

Printing" and "glasses" may not sound very familiar.

The easiest way to understand this is to apply printing on the outside of the temples, the part of the pattern that hangs over the ear of the frame.

This is the work of PAD printing.

See Fine's website for the principle explanation.

Craftsmen carefully print each temple.

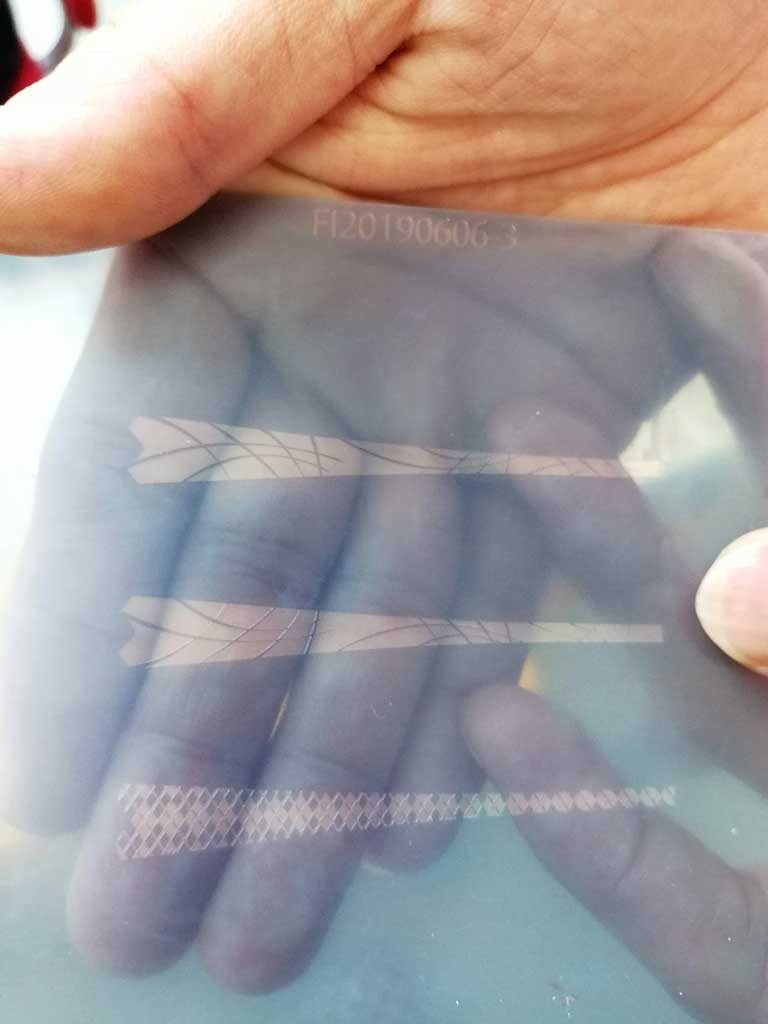

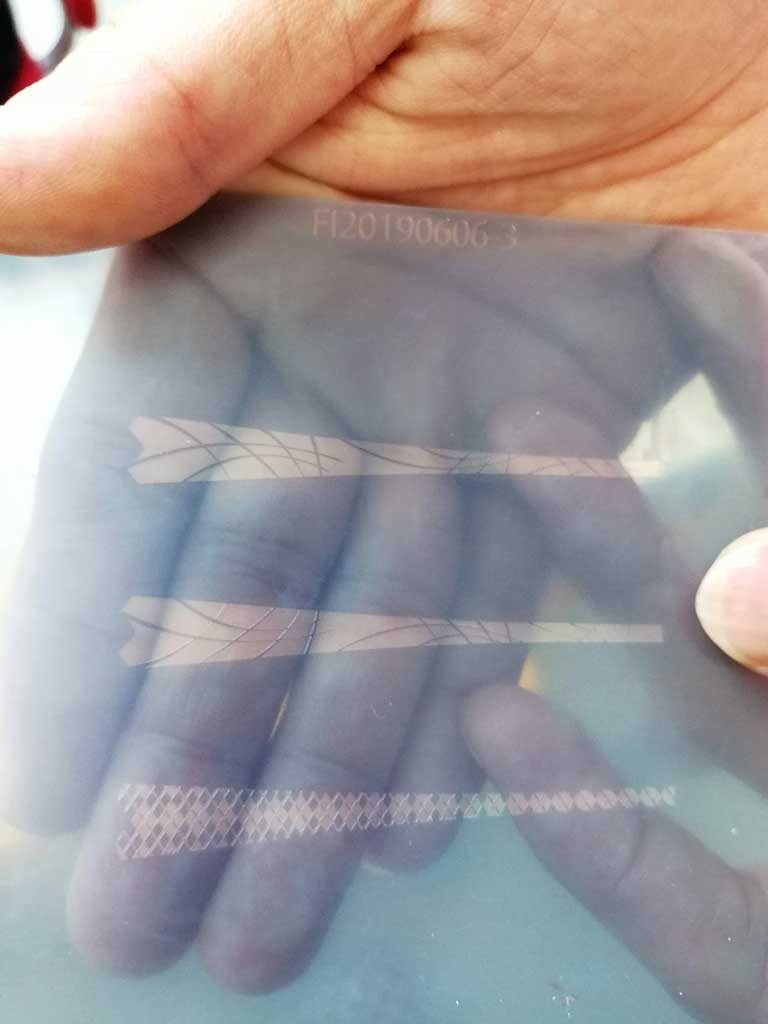

And here is the finished product

Glasses basically have symmetrical parts, so it is a craftsman's skill to print them neatly in the same position on the left and right sides.

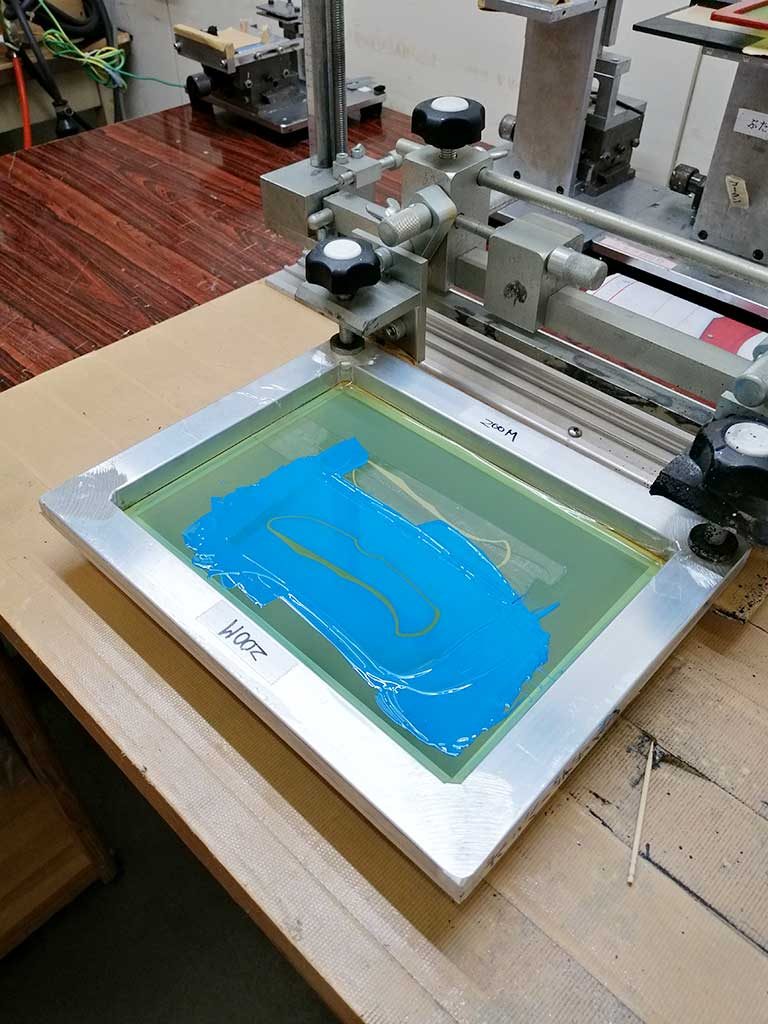

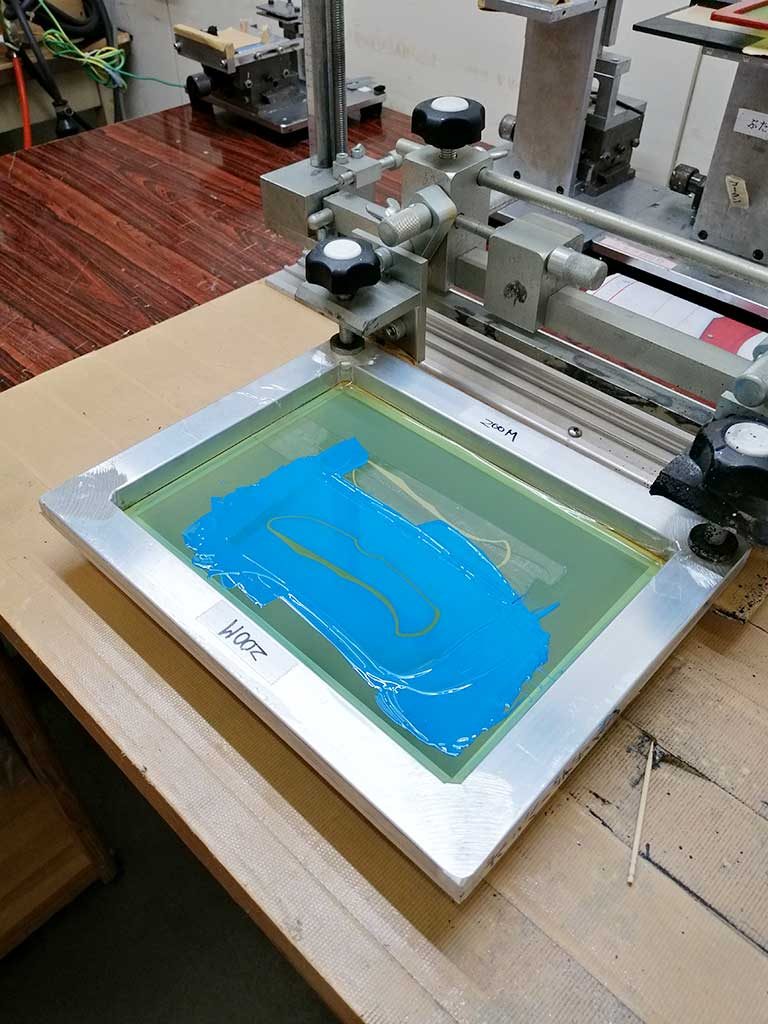

The next one is called silk screen printing.

I think the method was a product called "Print Gokko" used for New Year's cards and the like, but the principle is the same as that.

See Fine's website for the explanation of the principle 2

Actually, the technology that surprised me the most at Fine is not the above two printing methods, but inkjet printing.

See Fine's website for the explanation of the principle 3

Since the images were not allowed here, permission was granted to this female craftsman to create a work of art for fun.

Colors are sprayed on with an inkjet printer and hardened with UV.

There is a reason why inkjet printing on titanium and plastic was an "ooh" moment.

Generally, when we think of adding color to glasses, we think of cloisonne, painting, and plating, and if we want to add unevenness, we think of processes such as adding thickness with cloisonne, laser cutting, or pressing with a die to crush. However, Fine's inkjet printing process is capable of printing not only complex geometries, but also unevenness of up to 2 mm.

That's two millimeters. This is the first time I have ever known that an inkjet can accurately produce a level where the unevenness is perfectly visible with a finger.

Due to confidentiality obligations, I cannot say which brand it is, but I learned for the first time that some of the brands we carry were made using this process.

They are combining these new technologies with the plating, cloisonne, and painting techniques in which existing eyeglass production areas excel to create new designs.

It seems that many eyeglass designers are already taking on the challenge of designing with new technologies, so I look forward to seeing what the future holds.